We are professional manufacturer located in Nanjing China with decades of years of history providing wide range of industrial warehouse racks. OEM and ODM service is available with us. You are welcome to contact us for inquiry.

industrial warehouse dynamic storage carton flow gravity pallet rolling rack

industrial warehouse dynamic storage carton flow gravity pallet rolling rack

Carton Flow Rack

Carton Flow Rack,with its tilted shelves which improve visibility and order accuracy, is the perfect answer for split case or piece picking. The racking is developed from the medium duty racking. Aluminum or steel roller rail are equipped between a pair of beams per layer to form a slope of 3 degree, and under the driven of gravity, product moved from the loading side to the picking side of the rack, "first in first out" of goods are realized.

The height of the racking is normally lower than 2.5M and the loading capacity of each layer is 1000kg at the most. Shelves can also be adjusted to meet your picking height requirements.

Heavy duty pallet flow rack

Pallet flow rack, also known as "gravity flow," is a FIFO (first in, first out)

dynamic storage system. With pallet flow, you can achieve high-density storage while

maintaining a FIFO retrieval order. Pallet flow racking maximizes actual storage space

by minimizing aisles. Pallet flow systems can be designed to hold up to 20 pallets deep

in one lane and allow for quick and efficient inventory turnover.

Features

a) Unique aluminium or steel roller rail system which cartons move smoothly to the other side;

b) FIFO( first in first out) realized

c) Flexible design on size and structure according to box or carton size;

d) Dramatically improve warehouse efficiency

e) Keep labor cost down

f) Convenient access for two sides of assembly line

g) Perfect for warehouse slit case or piece picking

industrial warehouse dynamic storage carton flow gravity pallet rolling rack

More details

The basic essential factor for designing of heavy duty pallet racking and warehouse:

First

cargo and pallet:

1. Cargo weight (including pallet or steel box pallet).

2. the size of pallet and cargo.

3. the direction as the fork lifter enters the pallet to deposit and withdrawal cargo.

Second

forks lifter:

* model or technical parameter of Forklift.

* biggest height of lift and the shortest distance for the channel to be used of forklift.

Third

warehouse:

1. the plane size of warehouse.

2. the only high can be used of warehouse.

3. the direction and the request as cargo enter the storehouse.

We ensure the most productive warehouse pallet rack solution is provided whether working from your plans or developing a cost-effective layout that is just right for your needs. You are assured of the best designed, most efficient and safest racking.

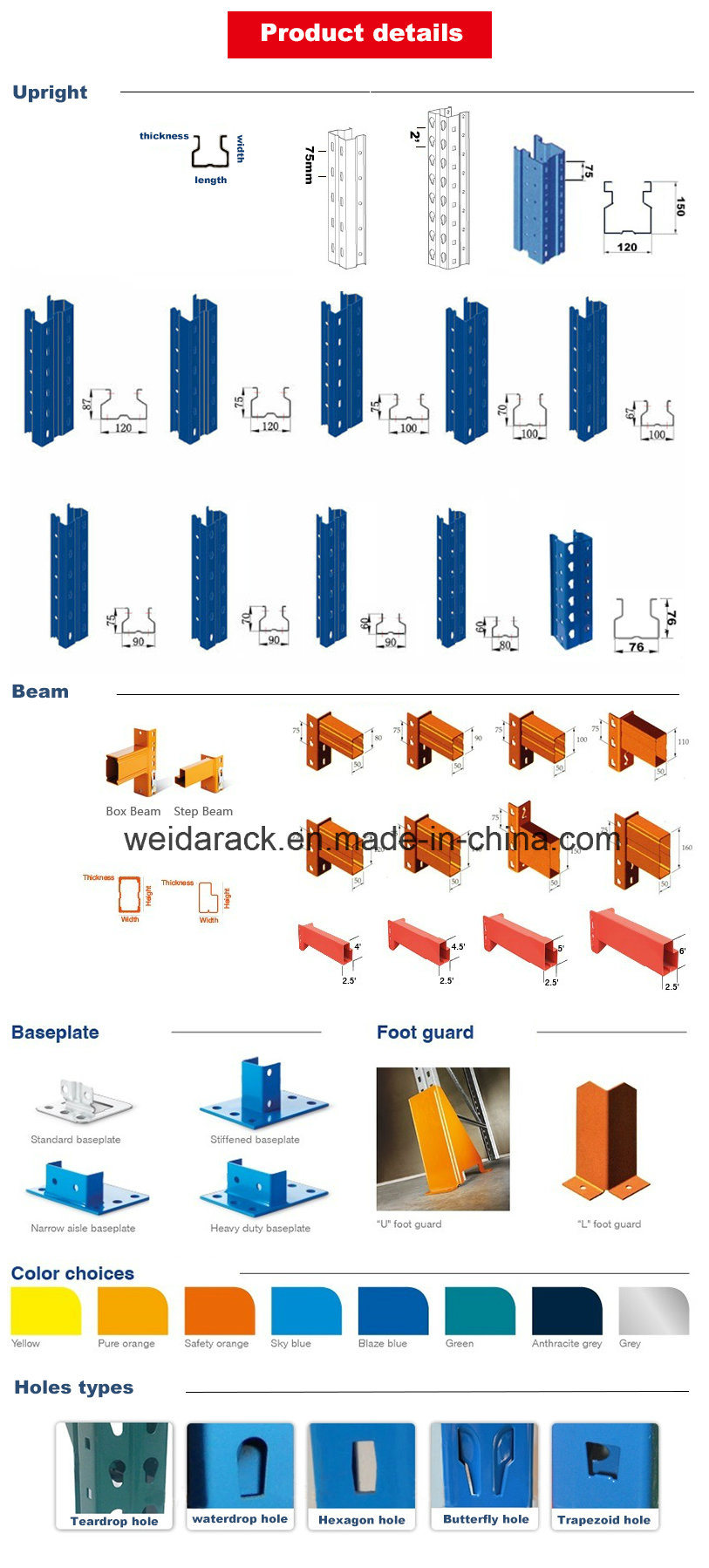

We also supply accessories like collumn guard, barrier, decking panel, adjustable base plate, wire mesh plate, truck rail etc, and other material handling equipment for warehouse storage.